Fluresh Tackles Immense Growth with Data-driven Microsoft Dynamics 365 Business Central and Silverleaf Cannabis Solution

In this case study, learn how Fluresh gained more insight into data from SilverLeaf than they ever have before.

In this case study, learn how Fluresh gained more insight into data from SilverLeaf than they ever have before.

Table of Content

For Fluresh, Grand Rapids, MI original dispensary, cannabis is so much more than a one-size fits all product. It offers nuanced solutions to numerous physical and emotional conditions. When you match a unique individual with the right product, the possibilities are endless. Fluresh provides cannabis products to fit its clients ever-dynamic life so each member of its community can experience cannabis’s potential in a way that feels right to them.

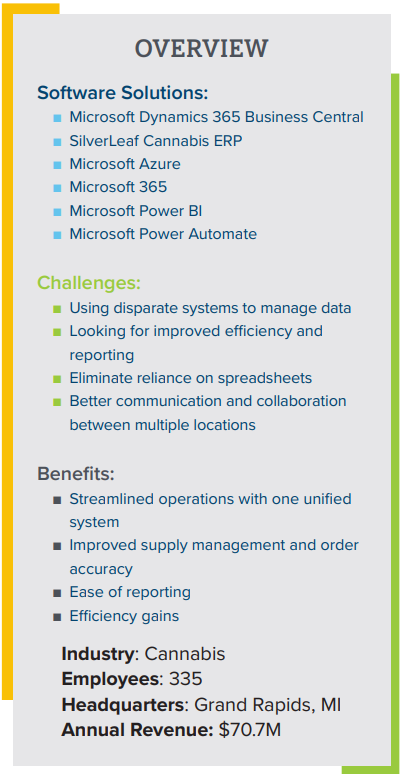

Fluresh, as a startup business in 2018, used QuickBooks for financial management but quickly outgrew its capabilities. That same year, they upgraded to Microsoft Dynamics NAV, hosted by Velosio for financial management for dispensary retail management for its three stores in Grand Rapids, Michigan. As Fluresh grew its cultivation and manufacturing, challenges also grew around compliance regulations and scheduling cultivation across two locations (Grand Rapids and Adrian, Michigan). The team was also looking for better data visibility and real time reporting.

outgrew its capabilities. That same year, they upgraded to Microsoft Dynamics NAV, hosted by Velosio for financial management for dispensary retail management for its three stores in Grand Rapids, Michigan. As Fluresh grew its cultivation and manufacturing, challenges also grew around compliance regulations and scheduling cultivation across two locations (Grand Rapids and Adrian, Michigan). The team was also looking for better data visibility and real time reporting.

“We were managing two facilities three-hours away from each other,” says Brian Hendricks, director of information systems at Fluresh. “One facility housed sales, and another took care of fulfillment, and there were a lot of spreadsheets floating between the two locations. We grew to a size where we couldn’t just have a couple people who knew what was going on – we needed something more robust so that everyone could be on the same page, working together within one system,” continues Hendricks.

Velosio implemented Microsoft Dynamics 365 Business Central (BC) for Fluresh in 2018, and it managed the company’s growth well. “It was an easy decision to move from NAV to BC because we were able to cut the hosting cost right out of the gate,” comments Hendricks. In 2019 Fluresh added raw materials handling and finished goods inventory into BC, and then decided to add SilverLeaf Cannabis ERP functionality to its system in 2022.

Goals for the Silverleaf project included tackling inventory costing – Fluresh uses standard costing throughout its grow and production. Fluresh also wanted to integrate with METRC, and manage manufacturing, cultivation, and distribution. “I’m really impressed by our finance team here at Fluresh – I think it’s the best in the industry,” says Hendricks. “Being close to Detroit, many team members have an automotive manufacturing background, so they were so thoughtful about costing and its importance in the cannabis industry at the start of the project – something that many times falls by the wayside as an afterthought,” continues Hendricks.

Cannabis is heavily regulated by tax code section 280E, which only allows cannabis companies to deduct their cost of goods sold, and not overhead expenses such as facility management, advertising, wages and salaries, or travel expenses, to name a few. It’s imperative that cannabis organizations define everything that goes into inventory cost to save as much as possible on tax implications. Fluresh was spending a week or so every quarter defining that quarter’s costing, and wanted to make sure it was automated within BC/Silverleaf for greater efficiency and accuracy.

“It’s invaluable to have the consultant spend time onsite to understand business processes firsthand.”

– Brian Hendricks

Director of Information Systems

Velosio implemented some of the Silverleaf solution remotely, but also made onsite trips to Michigan to work with the team directly. “It’s invaluable to have the consultant spend time onsite to understand business processes firsthand,” says Hendricks. Velosio conducted user interface testing onsite, and an additional 6-8 weeks of user acceptance testing remotely, prior to go-live. “We are a 24/7, two-shift business with a lot of day-to-day users who are young and haven’t used an ERP system before,” says Hendricks. “We knew that user acceptance would be key to project success, discovering early on that if users weren’t able to carry out tasks within the system, it wasn’t going to work,” adds Hendricks.

Fluresh has more insight into data than ever before. “The amount of data we can gather and analyze from Silverleaf is way more than we would even need,” says Hendricks. “QuickBooks, or the state system, METRC, or NAV are limited in the data they provide, which limits what you can do reporting-wise,” continues Hendricks. Fluresh has built a catalog of Power BI reports. “We have a guy who’s taken Power BI and run with it,” says Hendricks. “He has built cool reports for our executives on sales and inventory turns, providing a lot of insight,” adds Hendricks.

It’s also helpful to have all business data in one place, with one version of the truth. “We have much more visibility into the business without calling someone up to see what’s happening, or shuffling spreadsheets,” says Hendricks. The Microsoft ecosystem also helps with collaboration. “We were already a Microsoft company, but now there’s no risk of losing passwords, and we have used Power Automate to build out email automation and approval processes – I love it – it makes things so much easier,” says Hendricks.

BC and Silverleaf have also improved order accuracy. “We don’t have to worry about lost emails with sales orders, where the wrong thing was shipped,” says Hendricks. “The salespeople now input orders directly into BC and it is fulfilled by the warehouse team using handheld devices and integration with Warehouse Insight,” continues Hendricks. Warehouse Insight from Insight Works is seamlessly integrated into BC, ensuring that the physical warehouse remains in sync with Business Central data. The Fluresh warehouse team is also using Warehouse Insight for receiving, fulfillment, and inventory counts, increasing speed and accuracy. “What was once a manual process with pen and paper, we are now performing physical inventory counts on a monthly cadence but are moving towards cycle counting as we get a better handle on it,” says Hendricks. Fluresh recently went through a state audit, and it was smooth sailing from an inventory and financial standpoint.

Things change quickly in the cannabis industry, and Fluresh is looking to continuously improve its use of BC/Silverleaf. “We are looking at some white labeling and changing up some of our inventory items,” says Hendricks. “Since our go-live, many business processes have evolved and changed so it’s a constant upkeep of the system,” adds Hendricks.

The next big focus for Fluresh is around scheduling. “After we plant something, it’s another four to five months before we have a finished good,” describes Hendricks. “We need to better schedule finished goods with demand and yield, and budgeting for staffing, and more. We are looking into how much we can automate and build reports around, to see what’s happening in the future as opposed to just today, which will replace a lot of tribal knowledge with data,” says Hendricks.